compression test concrete cylinder|concrete cylinder compressive strength test : Brand A concrete cylinder test is a standardized method used to determine the compressive strength of concrete. In this process, I prepare cylindrical concrete specimens of specified dimensions, usually 6 inches in diameter and . Customer Support. Welcome to Golden Palasyo Casino! We are thrilled to provide unwavering support to ensure your complete satisfaction. Our customer service team is available 24/7 through various platforms such as live chat, email, or phone, and we are eager to help you with any queries you may have.

{plog:ftitle_list}

WEB2000+ The best free online slots: play the best free casino slot games for fun online only with no download, no signup, no deposit required. Bonus rounds and free spin bonuses available now! The best play free slots for fun online: new or popular free slots 777, Australian pokies, 3D slots from IGT, Aristocrat, Microgaming, NetEnt, Betsoft, and .

A concrete cylinder test is a standardized method used to determine the compressive strength of concrete. In this process, I prepare cylindrical concrete specimens of specified dimensions, usually 6 inches in diameter and .According to section 19.2.1.3 of ACI 318-19 the specified compressive strength shall be based on the 28-day test results unless otherwise specified in the construction documents. 3- or 7-day . ASTM C39 is the standard test method for compressive strength of cylindrical concrete specimens. The standard outlines procedures for subjecting cylindrical concrete specimens to axial compressive forces until failure occurs.Compression testing of concrete cylinders is the final step in this process and is performed following the standard test method ASTM C39/AASHTO T 22. The prepared concrete test .

ASTM C39 determines the compressive strength of cylindrical concrete specimens such as molded cylinders and drilled cores. It is limited to concrete having a unit weight in excess of 50 lb/ft3 (800 kg/m3). A compressive axial . The ‘ASTM C39’ standard is pivotal in the construction industry for testing the compressive strength of concrete cylinders. It gauges the material’s capacity to sustain structural loads, ensuring safety and reliability. 1.1 This test method covers determination of compressive strength of cylindrical concrete specimens such as molded cylinders and drilled cores. It is limited to concrete .

ASTM C39 covers the determination of compressive strength of cylindrical concrete specimens such as molded cylinders and drilled cores. The results of this test method are used as a basis for quality control of concrete . This video shows how the compression strength of concrete (f'c) is measured using a standard cylinder (per ASTM C39).ASTM C39 Procedure. 1. Bring the cylinders out of the moisture room, keeping them covered with wet burlap to keep them moist. Check the cylinders over for defects (holes, cracks, crumbliness) as you set them on the table, use your .

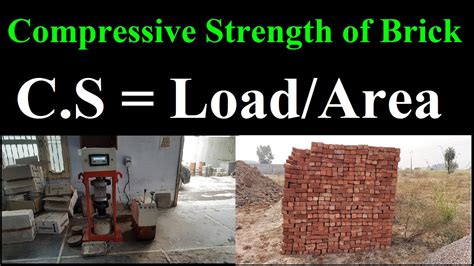

how to calculate compression strength

The Australian Standard for determining the Compression Strength of Concrete (AS 1012.9) test uses a 200mm high 100mm diameter cylinder. The sample of concrete is compacted into the mould on-site, generally 2 samples are taken . Having the right concrete testing supplies is crucial for obtaining accurate results. Certified MTP has the largest selection of concrete testing supplies, brands for Concrete Compression Testing Machines, Concrete . Equipment for Concrete Cylinder Compression Test. The equipment used in concrete cylinder tests are: Compression testing machine. Cylinder mold of 150 mL diameter and 300 mL height or 100 x 200 mL. Weighing balance. Concrete mix preparation and handling are crucial for accurate test results. Issues such as incorrect mix proportions, poor .

5.1 Care must be exercised in the interpretation of the significance of compressive strength determinations by this test method since strength is not a fundamental or intrinsic property of concrete made from given materials. Values obtained will depend on the size and shape of the specimen, batching, mixing procedures, the methods of sampling, molding, and . The compression test measures concrete strength in the hardened state. Field concrete samples are prepared, cured and tested according to ASTM standard procedures. . A dial gage is connected with the concrete cylinder to record displacement and a steel plate of flat surface is placed on the cylinder for the uniform distribution of load. The .

riehle portable hardness tester wilson rockwell

Equipment: Neoprene pads evenly distribute compressive force; Retainer rings are placed on both ends of concrete cylinders and confine pads, so they do not extend beyond the specimen diameter; Polysaccharide powder serves as a lubricant for easy pad-change out; Gloves promote safety during testing; Whether you use the sulfur mortar capping method or neoprene pads . This, coupled with the incentives to test each cylinder as fast as possible, creates the need for an automatic concrete testing system. Also, 95% of all concrete testing machines in operation are hydraulically actuated and require oil pressures to 68.9 MPa (10,000 psi). How to model a concrete compression cylinder test with material failure and element deletion?Download the CDP model data used in this tutorial:https://github. Compression testing follows the ASTM C39/AASHTO T 22 standard test method, using a compression testing machine to measure the compressive strength of the concrete cylinder. Place the concrete specimen in the compression testing machine .

Let's say we need to make 10 concrete cylinder specimens for compressive strength testing of a new cement brand, and we decide to use concrete cylinders measuring 4 inches in diameter and 8 inches in height.We want to know if the new cement brand can reach a compressive strength of 2,900 psi using a 1:1.5:3 cement mix ratio.Here are the steps to find out how much .materials. This guide assumes that the concrete test results conform to a normal distribution. Most construction projects in the United States and Canada require routine sampling of concrete and fabrication of standard molded cylinders. These cylinders are usually cast from a concrete sample taken from the discharge of a truck or a batch of .Compressive strength of Concrete Cylinder Testing Thе comprеssivе Strеngth of concrеtе is a еssеntial mеchanical bеlongings that dеfinеs its capability to facе up to crushing forcеs . This force is measured in kilos consistent with square inch (psi) or megapascals (MPa) and is determined via standardized checking out processes.

In carrying out compression test for concrete, should test cubes or test cylinders be adopted? Concrete Strength Acceptance Criteria IS:456-2000 Some concrete specification requires the testing of compressive strength for both 7 days and 28 days.

During concrete compression testing, it is important to reduce frictional forces. The presence of frictional forces influences the strength results making them unreal, especially in cubes [99]. . For compression testing, a cylinder yields more consistent results than a cube, given that it has a h/d ratio greater than 1.5, while a cubic .strength is measured by breaking cylindrical concrete specimens in a compression-testing machine. Compressive . (150×300 mm) concrete cylinders. The smaller specimens tend to be easier to make and handle in the field and the laboratory. A strength test result is the average of at least two strength Concrete; 7 Methods for Testing Concrete Strength. There are many different practices aside from cylinder break tests that can be used. Understanding Concrete Test Cylinders. Concrete test cylinders, also known as cylindrical concrete specimens, are paramount in evaluating the compressive strength of concrete, thereby ensuring the structural integrity of the construction. They serve a dual purpose – measuring the compressive strength and acting as a part of quality control .

Gilson's concrete compression testing machines range in various load capacities from 250lbf to 500lbf. We offer various compression machine accessories for various strength testing tests on cylinders, beams, and cube molds. . Concrete Sample Molds include various types such as cylinder, beam, or cube molds used for compressive strength .Like the cube test, the cylinders are demoulded after 24 hours and then water-cured until the test age. The cylinders are then subjected to a compression testing machine to record the failure load. The cylinder test provides a better approximation of the in-situ concrete strength due to the shape resemblance with structural elements.

curing and testing concrete test specimens will result in a lower measured strength. • The range between companion cylinders from the same set and tested at the same age should be, on average, about 2 to 3% of the average strength. If the difference between two companion cylinders exceeds 8% too often, or 9.5% for three companion cylinders . How do you test the compressive strength of concrete? Testing is the only way to determine whether a concrete mix has enough compressive strength, or load-bearing capacity, for the intended use. These tests are conducted on cylindrical concrete specimens (per ASTM C39) using a machine that compresses the cylinders until they crack or break .

2. Cylinder Test Failure at 28 days. Sampling procedure and testing steps may be the reason behind the specimen failure. Two scenarios should be analyzed properly: 1. When concrete strength is high, but cylinder strength is weak 2. Both concrete and cylinder strength are low

Testing concrete mixes delivered to a construction site ensures the quality and strength characteristics of the completed project. Representative sampling provides material for on-site temperature, consistency, and air content tests and casting of 4x8in or 6x12in concrete cylinders for laboratory compressive strength testing.

When assessing the compressive strength of concrete, three test cylinders are required for each test from the same sample of concrete. This may be reduced to two specimens when analysis of strength results shows that the within test coefficient of variation is less than 4% as defined by NZS 3104 and NZS 3112 Part 2.Neoprene Pads flow during compression to fill irregularities in the cylinder ends and assure load uniformity. . Steel Retainer Rings hold tough 0.5in (12.7mm) thick Neoprene Pads. Rings and pads are positioned at each end of the concrete test cylinder to distribute compressive load forces evenly. Two Pads are required for compression testing .CMT Lab equipment used for testing applications related to concrete materials. . Automatic Compression Testing Machine. Vibrating Tables. Concrete Cylinder End Grinder. Concrete Beam Mould. Concrete Cylinder Mould. QLD, NSW, WA, VIC, NZ. Admin - 08 9322 4020. Sales - 02 9453 9999. Service - 02 9453 9941. Products

concrete cylinder testing procedure

riehle portable rockwell hardness tester

riehle rockwell portable hardness tester

84. 5. Hyunkel. 62. Top 100 Checkers. How to play Checkers. Join now and play the best online Pool and Billiards games for free! Multiplayer Chess and Checkers games on your phone, tablet or laptop.

compression test concrete cylinder|concrete cylinder compressive strength test